Are you Calibrating Your Spirometer & 3L Syringe?

Are you Properly Calibrating your Spirometer and 3L Syringe?

If you’re conducting spirometry testing, you are likely performing daily and weekly calibrations utilizing a 3L calibration syringe. A standard 3-liter syringe is used to calibrate Pulmonary Function Testing, or spirometry equipment including the Depisteo Spirolyser® Q13® Spirometer, and the Benson Medical CCS-200 Spirometer.

Producing accurate and repeatable spirograms is especially critical for use for OSHA compliant programs. Prior to a day of testing, you must calibrate your spirometer using the syringe. In addition, a documented weekly linearity check is also required. (3 x of each time interval in succession PLUS your normal daily calibration check.)

What does a calibration syringe do?

The 3L syringe provides an easy and reliable method of calibrating and measuring the accuracy of respiratory volume-measuring equipment in the field. One calibrated 3L syringe is normally supplied with each new instrument and provides you with a fixed mechanical standard. Flow volume verification is performed by injecting a known volume (typically three liters) at various flow rates (½, 3, and 6 second intervals). Achieving accurate volumes at different flow rates demonstrates that volume measurement is independent of the flow rate. This is important because pulmonary function tests require accurate volume measurements at different flow rates that the spirometer will measure from patients.

Tips for performing an accurate spirometer calibration

Be sure to position the syringe on a flat, level surface. Use one hand to gently stabilize the syringe and the other to push or pull the piston rod directly in/out of the syringe. If an in-line filter is used in spirometry testing, then it must also be used during recalibrations and verifications. Start with the syringe piston completely pulled out, then smoothly push it in until you gently bump the piston head against the inside of the syringe. Try to have a slow, consistent motion, and do not start or stop too abruptly. However, if you’re going to err on one side or the other, it’s better to start fast and then slow down as you get towards the end of the time period of the stroke. A complete inspiratory syringe stroke is the exact opposite. Start with the syringe piston completely pushed in, then pull it out smoothly until you gently bump the piston head against the inside of the syringe.

How to know if your spirometer needs calibration

If a device fails its calibration verification, then a new calibration procedure or equipment maintenance is required. A dropped or damaged syringe should always be considered out of calibration until it is checked.

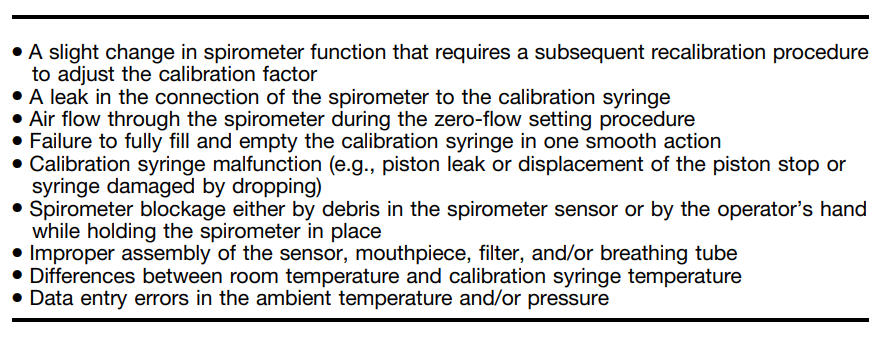

Potential Reasons for Calibration Verification Failure

STANDARDIZATION OF SPIROMETRY 2019 UPDATE. AN OFFICIAL AMERICAN THORACIC SOCIETY AND EUROPEAN RESPIRATORY SOCIETY TECHNICAL STATEMENT ARTICLE IN AMERICAN JOURNAL OF RESPIRATORY AND CRITICAL CARE MEDICINE · OCTOBER 2019

NEW 3L Syringe Calibration and Repair Services from e3

Of course, daily spirometer calibrations are a waste of your precious time if your 3L syringe isn’t working properly. If you’re having any of the calibration failures above, e3 Diagnostics is here to help.

In addition, the American Thoracic Society and NIOSH recommend that you calibrate your 3L syringe annually.

That’s why e3 Diagnostics Occupational Health Solutions has a NEW SERVICE to repair and calibrate your 3L syringe and help you stay up and running. Contact us today to schedule your calibration or repair service.